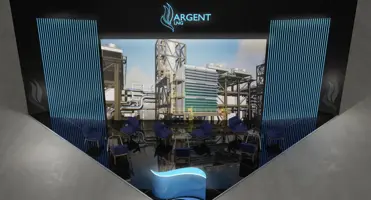

Why was it important for Air Liquide to showcase its hydrogen liquefier at Gastech?

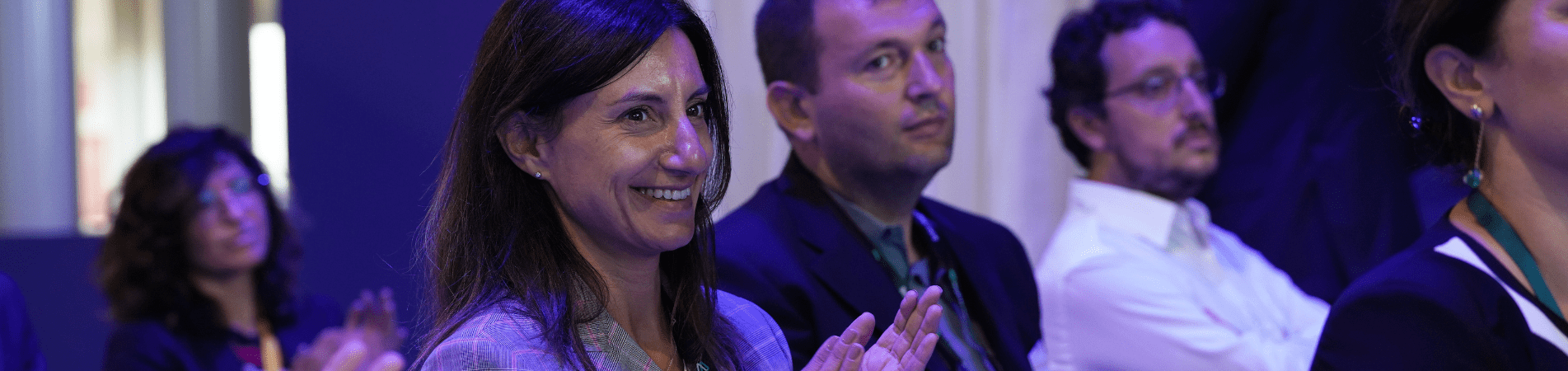

Gastech is one of the most significant energy events globally, bringing together decision-makers, innovators, and policy shapers. It was a perfect place for us to demonstrate that hydrogen is not just a future energy carrier - it’s already operational at an industrial scale.

We showcased our North Las Vegas Liquid hydrogen plant, one of the world’s largest, which produces up to 30 tonnes per day (TPD) of liquid hydrogen (for industrial and mobility customers) using Air Liquide’s proprietary steam methane reforming and liquefier technologies. It’s more than a plant - it’s a concrete illustration that large-scale, low-carbon hydrogen infrastructure is real and functional today.

What is Air Liquide's specific expertise in the area of hydrogen liquefaction?

Air Liquide is mastering the entire hydrogen value chain, from production to liquefaction to distribution. We have over 60 years of hydrogen expertise, with multiple Liquid Hydrogen (LH₂) plants operating worldwide - either owned and operated by Air Liquide or delivered to customers.

Our experience has enabled us to scale hydrogen liquefaction and introduce cutting-edge technology into real-world operations. The North Las Vegas plant is a reflection of this leadership and a foundation for what’s next.

What are the performance goals for future 100+ TPD LH₂ plants, and how is Air Liquide working to reduce energy consumption?

We’re targeting energy consumption levels below 7 kWh per kilogram of liquid hydrogen in our next-generation plants, and we believe this is an achievable goal, even lower in some cases. To get there, we’re focusing on two main levers:

- Enhanced precooling technologies that provide higher economies of scale above 80 TPD.- Advanced hydrogen expanders, where we leverage our deep cryogenics and energy recovery expertise to improve efficiency.

Our liquefaction plants therefore play a crucial role as vital platforms for continuous learning, where we have the ability to refine our processes and optimise technologies to support future advancements.

How did you manage to maintain high purity levels in the North Las Vegas plant design?

When designing North Las Vegas, we anticipated potential variations in hydrogen source impurities, so we built flexibility into the adsorption system. Now, with operational experience, we’ve optimized the adsorption and regeneration cycles to boost efficiency.

With a better understanding of impurity profiles, we can tailor each new plant’s design—whether it’s by reducing adsorption times, enhancing regeneration techniques, or adapting sieve bed sizing. This adaptability ensures our systems are both robust and efficient and allows us to maintain a high-purity level.

Can traditional activation methods be leveraged for large-scale ortho-para-H2 catalyst systems*?

Not really. Traditional activation methods were designed for lab-scale or small systems. In large industrial plants, the thermal inertia and volume are much higher, which can cause inefficiencies or even process instability if activation isn’t properly managed.

We’ve developed dedicated activation protocols for industrial-scale applications—covering everything from catalyst production to commissioning. These ensure the catalyst performs optimally while minimizing impurity risks and safeguarding long-term system reliability.

*Ortho-para-H2 catalyst system: an ortho-para-H2 catalyst system refers to a catalyst setup used to control the conversion between the ortho and para forms of molecular hydrogen

What’s next in Air Liquide’s hydrogen liquefaction roadmap?

One of our next focuses is the Project ENHANCE, located at the Port of Antwerp-Bruges. It’s a pioneering initiative that aims to build one of the world’s first large-scale LH₂ plants powered by renewable ammonia instead of natural gas.

Ammonia offers a promising alternative hydrogen carrier, and this project combines our expertise in ammonia cracking and liquefaction. By using renewable ammonia as a feedstock, we can drastically reduce CO₂ emissions while enabling a dependable liquid hydrogen supply for heavy mobility, shipping, and later, aviation.

More globally, we are drawing on our expertise in H2 liquefaction to bring a variety of innovative technology solutions to our customers to contribute to decarbonize the industry and support the energy transition.